Manufacturing medical devices is complex.

But it's all we do.

End-to-end contract assembly of medical devices & manufacture of their components.

We manufacture success

We scale production of our clients’ medical devices and components with consistent quality, process and regulatory compliance. From securing the supply chain to final packaging, our clients entrust us to take care of every detail.

Ready to solve your Medical Device production challenges?

END-TO-END THINKING

Providing a single partner solution

We start by understanding your design, and offer Design for Manufacturing & Assembly expertise. We source materials and negotiate with trusted suppliers for a cost-efficient and reliable supply chain. We provide final assembly, typically fabricating all or most of the product’s components, with automated solutions; all while meeting quality and regulatory standards, including Clean Room and sterilization capabilities. Moreover, we provide complete labeling, lot tracking, and final packaging.

Our end-to-end approach allows our clients to focus on their business and trust the production details to us.

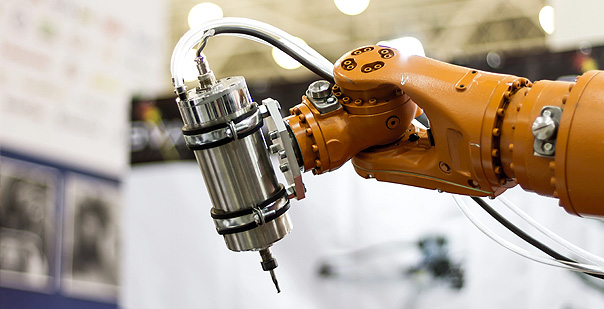

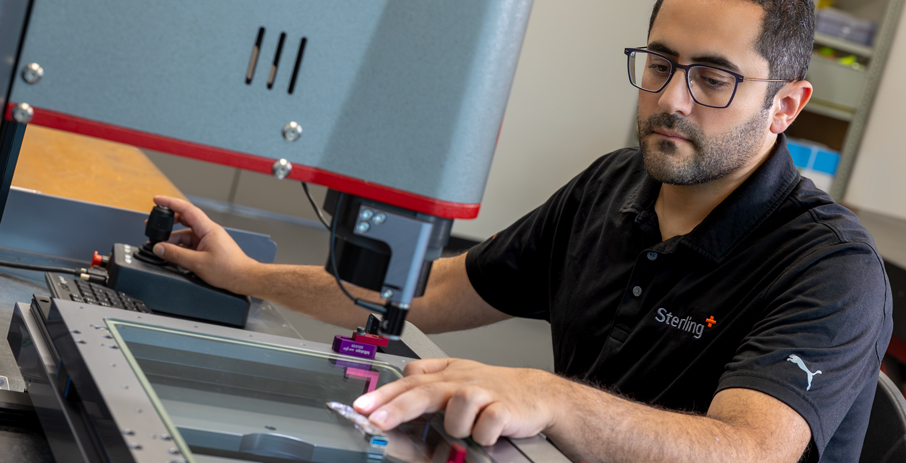

Assembly & Manufacturing

The right tools for the job

We offer a broad range of assembly & fabrication capabilities, from Clean Room assembly to volume automation; from complex digital devices to single-use products; .

Quality & Certification

Quality is a foundation for trust

Process & Design

Your design, refined

From manufacturing transfers to Design for Manufacturing (DFM) to Continuous Improvement, we help our clients scale their products efficiently.

Commitment

Making success simple

Why Choose Us

Why Sterling?

We specialize.

Manufacturing for medical means the strictest process and quality controls are at the core of what we do, and who we are.

We manufacture success.

We are experienced.

We are here.

We are right-sized.

We treat small- and mid-sized projects with the same care as our largest-scale production runs.

We are well-priced.

With expertise in Design for Manufacturing (DFM) and sourcing, we optimize cost without sacrificing quality.