Automation

Fabrication, Assembly & Packaging

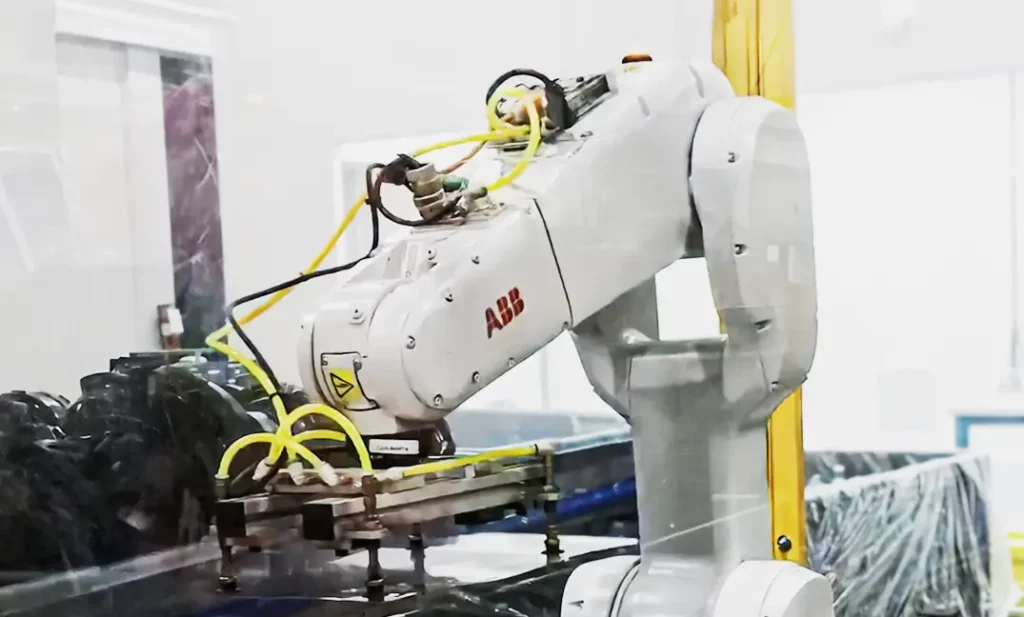

As a North American Contract Manufacturer, automated processes are central to our value proposition. Smart automation solutions can have significant impact on the profitability and reliability of our clients’ medical devices.

Capabilities

We offer a full range of automation integrations:

- Automated welding

- Automated injection molding

- Automated "pick & place"

- High speed assembly

- High speed packaging

- Vision inspection

- End of Arm Tooling (EOAT)

Our Engineered Solutions team looks at each step in the production journey, identifying the processes that benefit most from automated and robotic solutions. For high volume runs, savvy use of automation can add value at almost every step, from fabrication to assembly, quality control, labelling and packaging.

One of the key benefits of working with an experienced Medical Device contract manufacturer like Sterling is the experience gained from working on a wide range of products and manufacturing challenges. Those benefits extend to automation, where our deep expertise lends itself to analyzing and automating complex manufacturing techniques for perfect repeatability.

As with most of our processes, robotic/automation solutions can also be deployed within our Class 7 (10,000) Clean Room environments for projects with strict production requirements.