Process & Design: Build Any Device

At Sterling, we know that manufacturing is more than machining and technical capabilities; our reputation has been built on our process management and design thinking as much as on our deep technical expertise.

Our Approach for Any Device

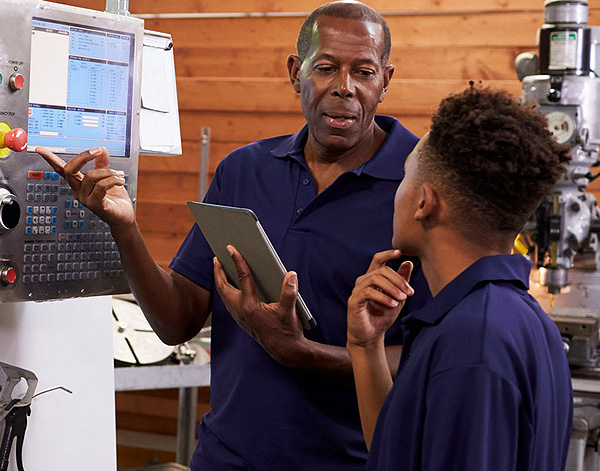

People

By bringing the right people to each project, each client gets access to the expertise that ensures success; from planning to designing, prototyping, production, and packaging, our team covers all aspects of scaled production.

Process

Repeatable quality — on time and on budget — is never an accident. We focus on scalability, repeatability, and regulatory compliance… with a continuous improvement (CI) mindset, always seeking greater cost and process efficiency.

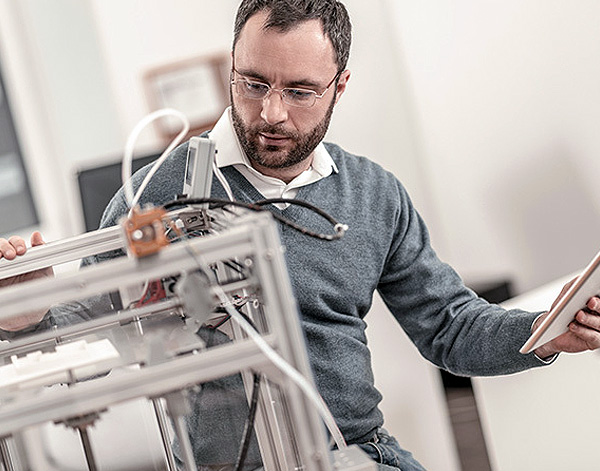

Technology

Our arsenal of assembly & manufacturing technologies enable us to produce a wide range of devices and components; Clean Rooms, advanced testing and packaging capabilities help us deliver end-to-end solutions.

Onboarding & Product Lifecycle

Our clients quickly realize that disciplined process is what makes us rise above the crowd. Our methodical approach to onboarding and product lifecycle ensures success; we work together to advance through each development stage, making sure we meet all the requirements to move the project to its next phase:

I. Design Assistance

At each phase, projects must pass through a stage-gate, making sure we’ve got everything we need to progress to the next stage

- Concept & planning

- Product development, ending with design lock

- Process development, ending with process lock

- Quality validation

II. Production

Kicking off production means strict adherence to our Quality Management System and processes, to ensure quality & compliance.

We practice Continuous Improvement; product & process changes follow strict procedures to ensure quality & repeatability.

R&D + Prototyping