Manufacturing Capabilities

With our advanced capabilities, we typically fabricate most — if not all — of our clients’ devices’ components. From simple devices, to disposables, to complex electronic devices… we have the tooling, skills, and experience to meet our customers’ diverse manufacturing requirements. We’re proud of the broad portfolio of innovative devices we’ve produced for our clients.

CNC Machining

- CNC Milling – 3, 4 & 5 axis milling

- CNC Turning – up to and including 7 axis turning with live tooling and sub-spindles

- CNC Threading

Welding

Robotic, Manual & Ultrasonic

- MIG and TIG (both Robotic and Manual)

- Laser Welding (small format)

- Ultrasonic Welding

- Ultrasonic Heat Staking

Metal Finishing

- Polishing – Wet and Dry

- Bead blasting

- Chrome plating

- Anodization

- Powder Coating

- Anti-Microbial Painting

- Electro-polishing

- Ultrasonic washing

Injection Molding & Low Pressure Molding

Class 7 Molding Facilities

- Multi-cavity insert molding

- Complex Over-Molding (metals and plastics)

- Low Pressure Over-Molding of electronics (encapsulation for biocompatibility)

- Liquid silicone rubber molding

Laser Tube Forming & Processing

- Large format 3KW 3-D fiber tube laser

- Small format for metal needles and tubing

- High throughput, high repeatability

- CNC tube forming and bending

- Laser marking

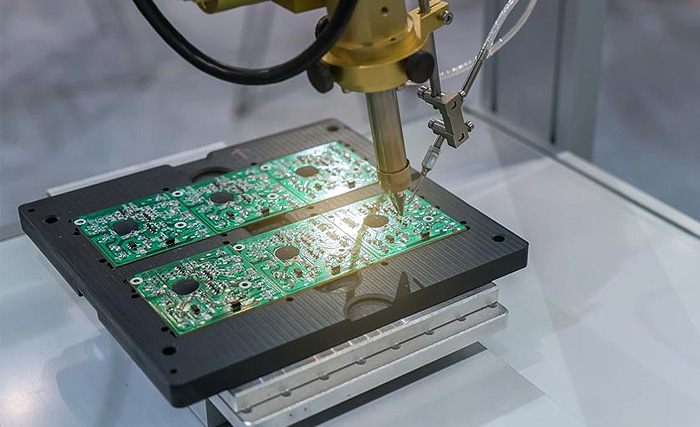

Electronics

- Soldering

- ESD assembly (Electro Static Discharge)

- PCB testing

- Post assembly testing

- Maintain multiple partners to assist with design and manufacturing of PCBs

- Optics

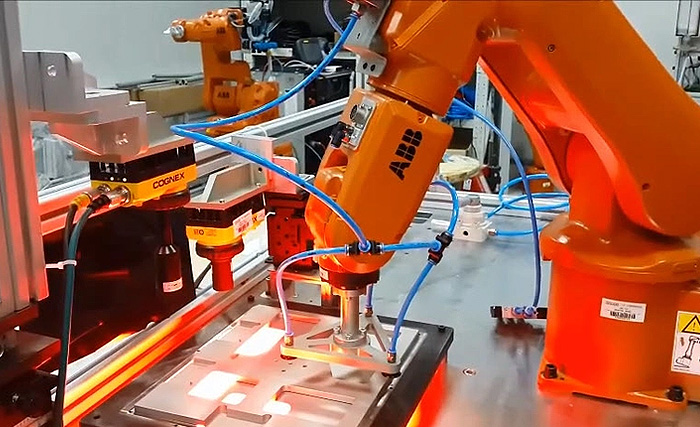

Automation

- Robotics

- High speed assembly

- High speed packaging

- Robotic Pick and Place

- Vision Inspection

- Inter-process Integration

Class 7 (10,000) Clean Room

- Injection Molding

- Ultrasonic Welding

- Low to High Volumes

- Assembly, kitting & packaging, IFUs, Sterilization Management (Gamma and ETO)